Comprehensive Guide to Checkweighers: Dynamic, In-Motion, Automatic, and High-Speed Checkweighers

Checkweighers are essential tools in today’s fast-paced manufacturing and packaging industries. Whether it’s ensuring quality control, reducing product waste, or complying with regulations, these machines are indispensable. In this article, we’ll dive into everything you need to know about dynamic checkweighers, in-motion checkweighers, automatic checkweighers, and high-speed checkweighers. By the end, you’ll understand their importance and how to select the best one for your business.

What Is a Checkweigher?

Definition and Basic Functionality

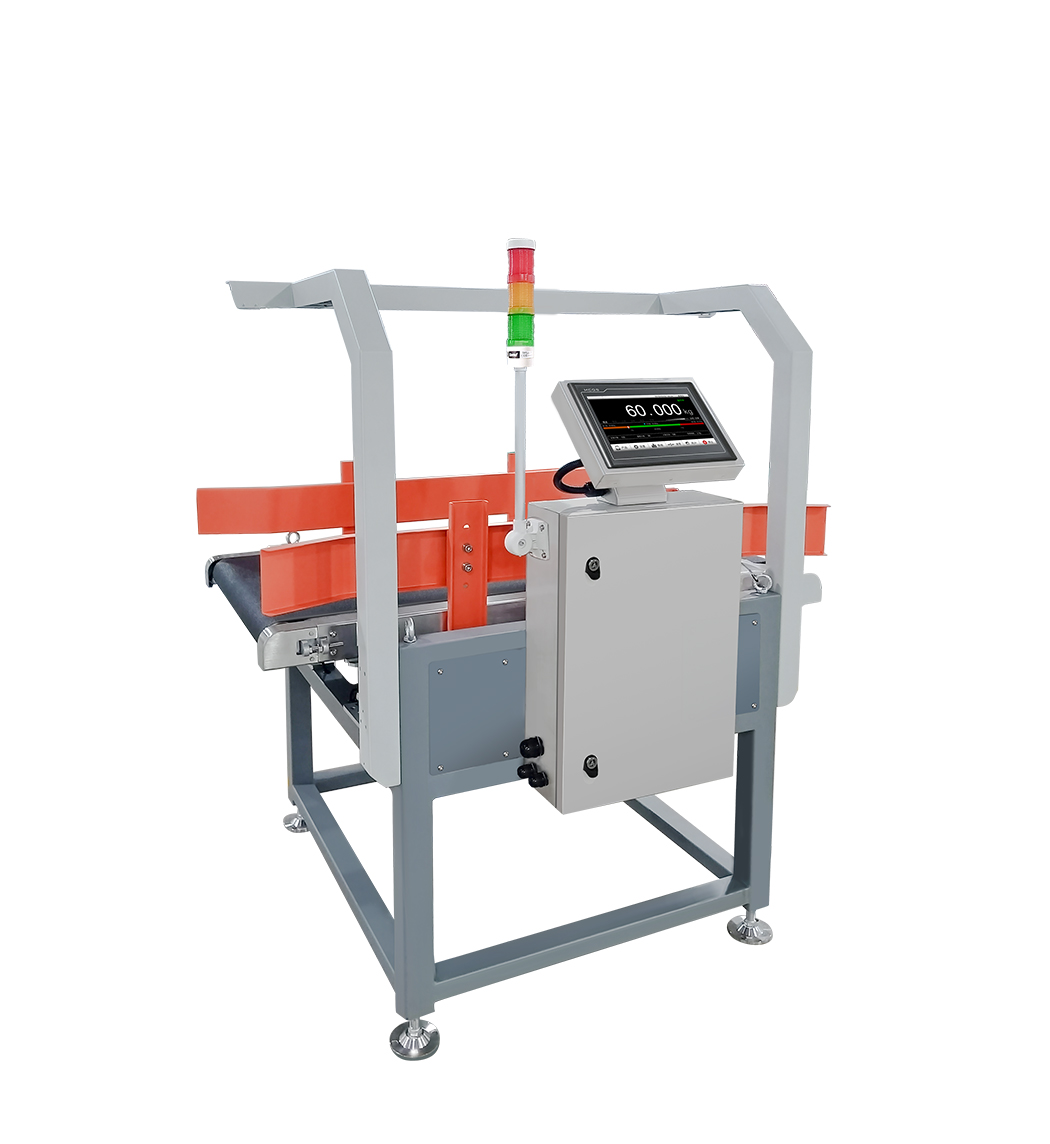

A checkweigher is a device used to measure the weight of items in a production line to ensure they meet specified weight requirements. Positioned at critical points in the packaging process, these machines automatically check weights in real time without disrupting workflow.

Importance of Checkweighers in Manufacturing and Packaging

Why are checkweighers so vital? They prevent underfilled or overfilled products from reaching the customer, protecting both brand reputation and customer satisfaction. Moreover, they ensure compliance with industry regulations, avoiding costly fines or recalls.

Types of Checkweighers

Dynamic Checkweigher

Dynamic checkweighers operate in real-time, weighing products as they pass through a conveyor system. They’re perfect for high-volume environments, delivering rapid and accurate results.

Features and Benefits

Weighs products continuously without stopping.

Highly adaptable to various product sizes and weights.

Reduces manual labor and errors.

Common Applications

Dynamic checkweighers are commonly used in the food, beverage, and pharmaceutical industries, where precision and speed are critical.

In-Motion Checkweigher

In-motion checkweighers weigh products as they move along the production line. Unlike static systems, these machines allow for seamless operation without halting production.

How It Works

An in-motion checkweigher uses advanced sensors and load cells to weigh products in transit. It automatically removes items that don’t meet weight standards.

Industries That Use In-Motion Checkweighers

Industries like logistics, e-commerce, and personal care rely heavily on in-motion checkweighers to maintain efficiency in high-speed operations.

Automatic Checkweighers

Automatic checkweighers are integrated into production lines for hands-free operation. They’re designed to work autonomously, reducing human intervention and improving productivity.

Key Features

Fully automated weight checks.

Compatible with other automated systems such as labelers and sorters.

Reduces downtime with minimal manual input.

Integration with Automated Production Lines

In industries like pharmaceuticals, automatic checkweighers seamlessly connect with robotics and conveyor systems, ensuring a smooth workflow.

High-Speed Checkweigher

High-speed checkweighers are built for rapid production environments where speed and accuracy are paramount.

Capabilities and Accuracy

Despite their incredible speed, these checkweighers maintain top-tier accuracy. They’re equipped with cutting-edge sensors and algorithms to handle thousands of products per hour.

Ideal Use Cases

High-speed checkweighers are best suited for large-scale manufacturing facilities, such as those in food packaging, cosmetics, and electronics.

How Checkweighers Improve Efficiency and Accuracy

Reducing Manual Errors

Human errors in weight verification can lead to costly mistakes. Checkweighers automate this process, ensuring accuracy every time.

Enhancing Quality Control

By identifying underfilled or overfilled products, checkweighers ensure that only items meeting strict quality standards reach customers.

Meeting Regulatory Compliance Standards

From food safety laws to pharmaceutical regulations, checkweighers help businesses comply with industry requirements, avoiding penalties or recalls.

Components and Technology Behind Checkweighers

Load Cells and Sensors

The backbone of any checkweigher lies in its load cells and sensors. These components measure the weight of products with incredible precision. Load cells convert the force exerted by a product’s weight into an electrical signal, which the system interprets to determine if the product falls within acceptable limits. High-quality sensors ensure consistent accuracy even in high-speed applications.

Conveyor Systems

Conveyor systems are essential for moving products through the checkweigher. Designed to handle different product sizes and weights, these systems ensure smooth, uninterrupted operation. Advanced conveyor systems can adjust speed dynamically, catering to the specific requirements of high-speed or heavy-duty applications.

Software and Data Analysis Capabilities

Modern checkweighers are equipped with software that collects and analyzes weight data in real time. This data can be used to monitor production trends, identify errors, and optimize processes. Many systems also feature connectivity options, allowing integration with IoT platforms for remote monitoring and control.

Benefits of Using Automatic and High-Speed Checkweighers

Speed and Precision

Automatic and high-speed checkweighers combine speed and accuracy, ensuring that even large-scale operations meet strict weight standards. They process thousands of products per hour without sacrificing quality, making them indispensable for fast-paced industries.

Cost Efficiency

While the initial investment in automatic or high-speed checkweighers can be significant, they offer long-term cost savings. By minimizing waste and reducing the need for manual labor, these systems quickly pay for themselves.

Scalability for Growing Businesses

As businesses expand, production demands increase. Automatic and high-speed checkweighers are designed to scale with your operations, accommodating higher throughput without compromising accuracy or efficiency.

Industries Benefiting from Checkweighers

Food and Beverage

In the food and beverage industry, consistent weight is critical for customer satisfaction and regulatory compliance. Checkweighers ensure that every package meets weight specifications, maintaining product integrity and preventing fines.

Pharmaceuticals

Precision is non-negotiable in the pharmaceutical sector. Checkweighers verify the weight of tablets, capsules, and packaged medicines, ensuring dosage accuracy and adherence to stringent health regulations.

Cosmetics and Personal Care

Cosmetic products often come in small containers, requiring highly accurate weight verification. Checkweighers help maintain consistency in product quantities, enhancing customer trust and brand reputation.

Logistics and E-commerce

In logistics and e-commerce, checkweighers ensure that packages are correctly weighed for shipping. This reduces errors, optimizes shipping costs, and improves overall efficiency in warehouse operations.

Choosing the Right Checkweigher for Your Needs

Factors to Consider

Selecting the right checkweigher depends on several factors:

Weight Range: Ensure the system can handle the minimum and maximum weight of your products.

Throughput Speed: Match the checkweigher’s speed capabilities with your production line’s requirements.

Accuracy Requirements: Choose a system that meets your industry’s precision standards.

Customization Options

Many manufacturers offer customizable checkweighers to suit specific needs. Options include adjustable conveyor sizes, enhanced software features, and specialized sensors for unique applications.

Comments

Post a Comment